3ADM 10 Axis Three Spindle CNC Drill Lines

PLEASE GET IN TOUCH WITH US FOR PRICE & SHIPPING

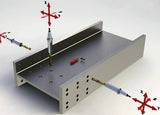

3ADM model, which has three spindles, can drill the profile from three sides independently, marking and tool changing simultaneously. Resetting the equipment to zero and setting it to the next drilling position are performed automatically by CNC.

ADM Drilling Lines, manufacturing first-class equipment like Mitsubishi and Siemens, has become prominent with quality and reliability with Akyapak’s solid after-sales support.

Through 3 independent servo spindle units on 3 ADM models, the profile can be drilled from 3 sides simultaneously. There is four tool capacity automatic tool changing system station for each spindle.

Beams can be drilled without driving them throughout the beams’ length of 500 mm. | 20” For instance, if the holes’ diameters are 10 mm | 3/8” and the distances between each hole are 40 mm, | 1,57”, the spindle can drill 12 holes without moving the beam, and that means you may save plenty of time within the operation.

And that means a very big time-saving. Also, there is one more advantage of the 3ADM system, which allows the user to make scribing and marking on three surfaces (Optional). 3-axis marking is also available as an option.

Firstly, the material to drill (profile, box profile, angle) is placed on the infeed conveyor. The workpiece, being held with the handle claw of the driving unit, is driven into the drilling machine, and the piece's position is set to zero by laser light. The drilled workpiece is moved to the angled bandsaw (optional) with the handle claw of the driving unit. Sawing can be performed at the desired length and angle (-45/+60”). Sawed rolls of material are driven to the output conveyor.

Features:

3 ADM 1200 CNC offers three spindles, three sub-axis, marking, scribing, tapping, countersinking, 40ft in/out feeding conveyor.

Capacity: 40' X 40'

Drilling Diameter: 3/8" - 1 1/2"

Scribing Tool: One on each side

Chip Conveyor: Yes

Miter Band Machine: Optional

• Equipped with servo motors

• three high speed 30 HP spindle motors

• Scribing up to 4 surfaces

• For the exterior surface of beams

• 40 characters

• Servo-driven rotating disk

• Roller linear guidance system

• Servo motor-driven ball screws

| Controller | Mitsubishi |

| Operating Range | Min. 7 7/8' x 3 5/32' |

| Max. 47 1/4" x 19 11/16" | |

| Drilling Units | 3 |

| Drill Diameter | 3/8" - 1 1/2" |

| 40 – 50 (U-drill only) | |

| Thread Tapping (optional) | M12 – M24 |

| Drill Holder | BT40 |

| Spindle Speed | 50 – 3000 rpm |

| Spindle Power | 30 HP/103 lbf.ft |

| Spindle Torque | 206 lbf.ft |

| Toll Cooling System | MQL |

| Weight per Sf | 100 lbs |

| Workpiece Movement | Servomotor+planetary gearbox |

| Automatic Cross-Section Measuring | Standard |

| Machine Weight | 28,660 lbs |

| Dimensions | 7.9' x 23' x 10.5' |

| Central Lubrication for Linear Guides | Standard |

| D.O.T. Marking | Optional |

| Scribing Tool | On each side |

| Chip Conveyor | Standard |

| Miter Band Saw Integration | Optional |